Coal Fired Power Plant

Gas Combined Cycle Power Plant

Synchronous condenser

Waste-to-Energy plant

Geothermal

Wind energy

Coal Fired Power Plant

Gas Combined Cycle Power Plant

Synchronous condenser

Waste-to-Energy plant

Geothermal

Wind energy

Power & Renewables

Coal Fired Power Plant

Gas Combined Cycle Power Plant

Synchronous condenser

Waste-to-Energy plant

Geothermal

Wind energy

Coal Fired Power Plant

Gas Combined Cycle Power Plant

Synchronous condenser

Waste-to-Energy plant

Geothermal

Wind energy

Clean renewable energy from Mother Earth

Heat from the Earth provides a clean and sustainable energy source and is the core renewable power generation in some countries.

As your ideal and reliable partner, ABB offers complete turnkey instrumentation, control, electrical and optimization solutions for all geothermal power generation, helping customers while lowering the environmental impact

Turbines are comprised of subsystems working in unison to efficiently and safely produce power. ABB products are used throughout these subsystems, from the emergency stop button to the generator.

ABB’s proven products for wind turbines are designed and built to operate for long life cycles under the varied and harsh operating conditions common to turbines. ABB engineers with years of wind power experience help design the products and work with turbine manufacturers to correctly and efficiently integrate these products into turbine designs.

For more information visit ABB's website:

https://new.abb.com/motors-generators/segments/wind-power

ABB’s motors and generators often play a critical role in the plants in which they operate.

In many cases the complete process would be brought to a halt if the motor or generator stopped working. Downtime may result in considerable costs in terms of lost production, waste and damage, so the availability of this equipment is a top priority.

We supply genuine spare parts, spare part packages and maintenance kits for all ABB motors and generators. We can also provide exchange units for wind power generators. As we are the original equipment manufacturer, you can rely on us to supply the correct part. Where technology has advanced, we may be able to provide a part that is even better than the original. We can also help you to rationalize your on-site spare part stocks.

Key benefits

Our offerings:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/spares-and-consumables

A fully tailored service agreement gives you the best possible fit with your needs.

Our experts will help you to design the ideal agreement for you. The process starts with a free-of-charge risk analysis of all the motor and generator systems at your site. In addition, we will analyze your service requirements – carefully reviewing the condition of your equipment and its importance in your operations – and recommend the most appropriate service agreement.

Our service agreements take your competencies and resources into account and are based on the optimum way of sharing the work. In particular, when technical support or remote troubleshooting services are added to the agreement it becomes critical to have competent personnel present on-site. Based on our recommendation you can select the service elements to include in the agreement. For additional convenience, a number of service plans can be coordinated under a single agreement.

An ABB service agreement is the most efficient way to manage the total life cycle of the motors, generators and mechanical power transmission products at your plant, while minimizing production risks.

Key benefits

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/service-agreements-abb-motor-care

When a motor or generator needs replacing, do it the easy way - contact your local ABB representative.

Replacing existing equipment with a new ABB product is a great investment: the new unit’s superior efficiency and performance can ensure a very short payback time. Whether you select a new motor or generator from our wide range of standard items or choose a tailor made unit, we can generally optimize it to replace your existing equipment.

In most cases we will be able to adapt the electrical designs to make the replacement fully interchangeable with the original. Utilizing our know-how and experience, we can easily provide replacements for third party products.

For the plant operator this helps to minimize the downtime, required site work and risks. An added benefit of a tailor made, fully interchangeable replacement is that you may be able to keep your existing machine as a spare.

We will be pleased to help you evaluate the potential to increase production, reliability and availability as well as decrease energy and maintenance costs with a replacement product from ABB.

Key benefits

Our offering:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/replacements

Replacement units for the wind industry.

There are many benefits for wind farm owners and operators in having a replacement generator rapidly available if major generator damage occurs. Ordering a replacement unit from the factory will typically mean downtime of up to 20 weeks. Such a long period of downtime will naturally cause huge production losses.

To help our customers overcome this problem, we have developed the ABB replace and recycle service. As part of the service, we have established two storage facilities for rapid generator replacement. We store several units of the largest wind power generator fleets. These are located in Denmark (50 Hz generators) and the USA (60 Hz units).

The ‘recycle’ aspect of the service means that you exchange your damaged generator for the replacement unit. We repair and refurbish the damaged generators to as-new condition and place them in storage.

Wind farms that use our replace and recycle service have generators available for rapid replacement if a production unit gets damaged. This cuts downtime and reduces production losses.

With the market’s widest service network globally, and service engineers standing by to carry out repairs on-site or in authorized workshops, we can offer different repair options to match your needs.

Key benefits

Our offerings:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/repairs

On-site Repairs

Workshop Repairs

Technical support

Keep your processes running with ABB’s drive maintenance services

We offer maintenance services that cover everything from life cycle assessment through to detailed preventive maintenance programs. By performing regular maintenance we can maximize your drives reliability and keep your drives going longer.

When we carry out maintenance on your drives, we will take care of tasks pre-defined in product specific maintenance schedules. ABB’s extensive experience in drive maintenance means that we can optimize the service intervals according to the needs of different components and systems within your drives. We also offer drive-specific Preventive Maintenance kits with all the genuine parts you need.

For more information visit ABB's website:

http://new.abb.com/drives/services/maintenance

Our offerings:

Getting it completely right from the very start.

That’s the idea behind our professional installation and commissioning services. When you use these services you are making an investment in the long-term trouble free operation of your equipment.

We provide commissioning engineers with extensive experience in motors and generators. Their know-how, backed by the expertise of our design team, makes commissioning fast and smooth and lays the foundation for high reliability and efficiency.

Key benefits

Do you want the latest technology? But you don´t want to change your equipment? No problem.

We are not only committed to delivering the latest technology in new, world-class motors and generators, but also in the form of upgrades for older products. In fact, the potential for upgrading the installed base is one of the factors driving our constant efforts to develop world-leading technology.

In many cases plant operators can upgrade their existing ABB equipment by retrofitting it with new technology. Upgrades can deliver increased production capacity, lowered energy and maintenance costs and increased lifetime as well as better availability and reliability. We will be pleased to advise you on the feasibility of upgrading your ABB equipment.

Key benefits

Our offering:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/extensions-upgrades-and-retrofits

All equipment is subject to aging and the lifetime of components is limited. Therefore it’s important to take the right action to avoid an eventual component failure.

Hardware upgrades represent an effective way of extending the lifetime of a motor or generator. ABB’s turnkey hardware upgrade service uses the latest technology to deliver improved performance in terms of efficiency, reliability and safety.

Automatic Voltage Regulator upgrades for synchronous generators

The Automatic Voltage Regulator (AVR) upgrade service is designed to prevent unexpected generator downtime due to malfunctioning of the AVR, as well as providing ongoing technical support. Rather than replacing the old AVR with an identical unit, we offer upgrades with the new Unitrol AVR.

Control panel upgrades for synchronous motors

ABB has extensive experience in excitation systems for synchronous motors. ABB motor control panels (MCP) are carefully designed with reliable and high quality components to ensure high availability and reliability. Replacing old motor control equipment with a new state-of-the-art MCP is an investment in availability, reliability and functionality.

Brushless exciter upgrades for synchronous motors and generators

UNICITER® is a brushless exciter for upgrading synchronous motors and generators from conventional DC motor excitation to state-of-the-art rotating diode bridge technology. It is an ideal solution for replacing obsolete DC exciter motors. Upgrades of old DC or slip-ring excitation systems can be done on both ABB and non ABB synchronous motors and generators

Advanced services are designed to support your decision making process, helping you make choices that will maximize availability and reduce the risks associated with operating and maintaining motors and generators.

The solutions delivered not only cover management related decisions – on issues like the correct channeling of investment budgets - but also address highly technical concerns like diagnostics, prognostics, load optimization, and troubleshooting.

The solutions are oriented with life cycle management concepts so that, rather than concentrating only on the lowest cost of purchase, they focus on the lowest cost of operation over the lifetime of the asset

Our offerings:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/advanced-services

Our training courses are designed to give your people the specialized skills they need.

Key benefits

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/training

Training for Motors and Generators

Training is offered as in-class programs. In-class programs can be standard or customized, according to your requirements

Code Course name

K700 Rotating electrical machines theory, operation and maintenance

K701 Rotating electrical machines theory, operation and maintenance for oil, gas and petrochemical

industry

K702 Rotating electrical machines theory, operation and maintenance for marine industry

K703 Rotating electrical machines theory, operation and maintenance minerals and mining industry

K704 Diagnosis and condition monitoring of rotating electrical machines

K280 Ex Service seminar for motors and generators for hazardous areas

K251 Synchronous machines training, see link for more information

G911 Electrical machines operation and maintenance (german language)

Designed for larger turbines, ABB’s medium voltage full power converters are characterized by low parts count, high availability and low losses. The modular design allows easy customization to meet customer requirements. The converters are designed for nacelle or tower base installation and enable low cost and efficient cable installation. Fault ride-through and grid code compliance is also provided.

For more information visit ABB's website:

https://new.abb.com/power-converters-inverters/wind-turbines/utility-scale/pcs6000

In a direct drive application the turbine and the generator are integrated to form a compact and structurally integrated unit. The design gives free access to all parts for easy installation and maintenance. The simple and robust low speed rotor design with no separate excitation or cooling system results in minimum wear, reduced maintenance requirements, lower life cycle costs, and a long lifetime.

For more information visit ABB's website:

Low cost of ownership (purchase - running - downtime)

MS PMGs represent a very compact, slower speed solution offering the highest efficiency with low maintenance needs. ABB produced the world´s first MS PMG Multibrid-type design in 2000: this has the turbine main bearing and PM generator integrated with a single-stage gearbox.

For more information visit ABB's website:

Enhance and modernize your existing drives with upgrades and retrofits from ABB

Whenever you want to modernize your existing drives, contact ABB. We provide everything from expert advice through to implementation of the latest software and hardware upgrades.

Upgrades and retrofits will improve your drives’ reliability and performance, and extend their functionality. In addition, modernizing your drives ensures support and spares availability.

Modernization services are also available for drives other than ABB.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/upgrades-and-retrofits

Hardware Upgrade

Improve the performance of your drives and extend their functionality with ABB upgrades

Highlights

Control upgrade

Cost-efficient lifetime extension for your drive

Highlights

Retrofit service

Bringing drive technology up-to-date

Highlights

With ABB, the parts or exchange drives you need are always available

With ABB, the genuine spare parts and exchange units are always available wherever you need them. We provide spare parts for all drive types in the active and classic phases of their life cycle and for some drives in the limited phase. We will also help you select the optimal exchange unit with the correct features for your application. All ABB spares and exchange units come with a one year warranty.

Our offerings

For more information visit ABB's website:

http://new.abb.com/drives/services/spares-and-consumables

Genuine ABB spare parts: global on-time delivery

If a fault is detected within a drive, the right spare part can be delivered as soon as you need it.

Highlights

Drive Exchange service

Exchange operational problem with smooth reliability

Our fully functioning workshop-refurbished drives save you time and costs when replacing units or carrying out preventive maintenance.

Highlights

Optimal cost savings - Save up to 30% of the cost of a new drive, but with the equivalent performance, with our fully tested exchange units.

Trustworthy reliability - Exchange units are fully compatible with your original drives. They are tested according to original specifications and have a one-year warranty.

Green and sustainable - Your original drives are gone but not forgotten. They are either refurbished, used to refill exchange unit stock or recycled according to local regulations.

Allow your business to prosper!

Each ABB Drive Care agreement is designed to let you focus on your core business. With a service agreement matching your needs we can reduce the risk of unplanned downtime and make it easier for you to budget maintenance. This means better, more reliable drive performance, extended drive lifetime, and improved cost control.

Highlights

For more information visit ABB's website:

http://new.abb.com/drives/services/abb-drive-care

We offer you the world’s widest drives portfolio. Whenever you need to replace an entire drive - from ABB or any other drive manufacturer – we can take care of it.

We will help you select the optimal replacement drive with the correct features for your application.

Simply contact ABB or one of our third party company representatives to request a new drive or exchange unit. In urgent cases we will dispatch your exchange unit within 24 hours from the moment of order. We also offer express delivery services. If you need help with drive’s installation and commissioning, we can provide those services too.

For more information visit ABB's website:

http://new.abb.com/drives/services/replacement

Rely on ABB's repair service to restore your operations

Our drive repair services are fast and effective, helping you restore your operations quickly. ABB certified service engineers can provide both on-site repair and workshop repair services, supported by our extensive stock of genuine ABB parts.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/repairs/onsite-service-center

Workshop Repair service

Highlights

On-site Repair service

Highlights

Technical Support

Highlights

On-site Service Center

Highlights

Keep your processes running with ABB’s drive maintenance services

We offer maintenance services that cover everything from life cycle assessment through to detailed preventive maintenance programs. By performing regular maintenance we can maximize your drives reliability and keep your drives going longer.

When we carry out maintenance on your drives, we will take care of tasks pre-defined in product specific maintenance schedules. ABB’s extensive experience in drive maintenance means that we can optimize the service intervals according to the needs of different components and systems within your drives. We also offer drive-specific Preventive Maintenance kits with all the genuine parts you need.

For more information visit ABB's website:

http://new.abb.com/drives/services/maintenance

Our offerings:

Proper installation and commissioning are essential for all drives.

ABB-certified engineers can provide professional installation and commissioning services for you to optimize drives safety, availability and performance. Our expertise also helps you minimize installation and commissioning time and cost.

Installation

Ensure drives reliability right from the start

To help you to correctly install your drives and ensure reliable performance, ABB and third party authorized channel companies can offer you accurate advice and timely support, before and during the installation. On request, ABB certified engineers can also undertake the entire drive installation for you.

Commissioning

Optimize the availability and performance of a new drive application with professional commissioning

We offer services that help you get more from your drive from the moment it’s commissioned. ABB certified engineers will ensure that your drive is commissioned according to local safety regulations and adjust its parameters for the optimum reliability and performance. Well commissioned drives run better, more reliably, use less energy and have a longer life.

All startup information with process parameters will be saved in case an engineer needs to recall any information at a later date.

During the commissioning work, we can provide guidance on drive usage. More extensive training is available separately as an option.

For more information visit ABB's website:

http://new.abb.com/drives/services/installation-and-commissioning

Services for your applications needs

Engineering and consulting help in improving the performance of production processes and facilitates effective asset management. We leverage our network to provide the best solutions for you.

Our engineering and consulting services are based on production, safety and energy efficiency analyses of machines and systems. We take care of your specific requirements that you might have during procurement, operation and maintenance of your assets.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/engineering-and-consulting

Engineering Customization service

Tailored solutions for your application needs

Highlights

Functional Safety Assessment service

No compromise on safety and performance

Highlights

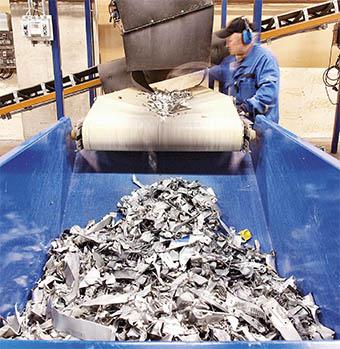

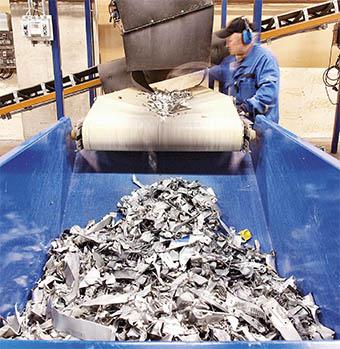

When your ABB drives reach the end of their lives, ABB’s End-of-life services will assist you with disposal and recycling

We behave in an environmentally responsible way throughout every drive’s life cycle, even when it reaches the end of its working life.

Disposal and recycling

We will remove and dispose of any ABB or non-ABB drive and associated equipment in line with the environmental regulations enforced within your country.

Contact your local ABB for further assistance

For more information visit ABB's website:

http://new.abb.com/drives/services/end-of-life-services

Always one step ahead

With the help of advanced services, your production, energy consumption and cost management can all be enhanced.

Our remote monitoring and energy efficiency solutions mean your business stays a step ahead. Accurate, real-time information about your energy consumption or drive events will facilitate you making the right decisions about your assets operations at the right time.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/advanced-services

Energy Appraisal service

Do more with less by improving energy efficiency

Highlights

Remote Condition Monitoring service

Always one step ahead – reveal your drive’s true potential

Highlights

Make best decisions – Combine your process know-how with analysis and recommendations by ABB professionals. Best decisions are made together.

Reduce the risk of unexpected downtime – Remote Condition Monitoring helps to anticipate possible faults, operational issues and maintenance needs. Equipment will perform better and last longer.

Monitor topics that are important to you – We can tailor our services to your needs and you can monitor the issues that interest you. Our experts are also always on hand to consult with you.

← Back

Generators

Generators for wind turbines

Direct drive wind generators

Doubly-fed wind generators

High speed induction generators

High speed permanent magnet wind generators

Medium speed PM wind generators

Services

Generator life cycle services

Spares and Consumables for generators

Service Agreements for generators

Replacement for generators

Repairs for generators

Maintenance for generators

Installation and Commissioning for generators

Extensions, upgrades and retrofits for generators

Advanced Services for generators

Training

Generator training

VSD life cycle services

Upgrades and Retrofits for drives

Spares and Consumables for drives

Service agreements - ABB Drive Care

Replacement for drives

Repairs for drives

Maintenance for drives

Installation and Commissioning for drives

Engineering and Consulting for drives

End-of-life services for drives

Advanced Services for drives

Variable speed drives - VSD

Wind converters

Medium voltage full power converter

LV full power converters

LV full power and doubly-fed converters

Please rotate your device to landscape orientation to use this application.

Please visit this application from a computer or tablet.