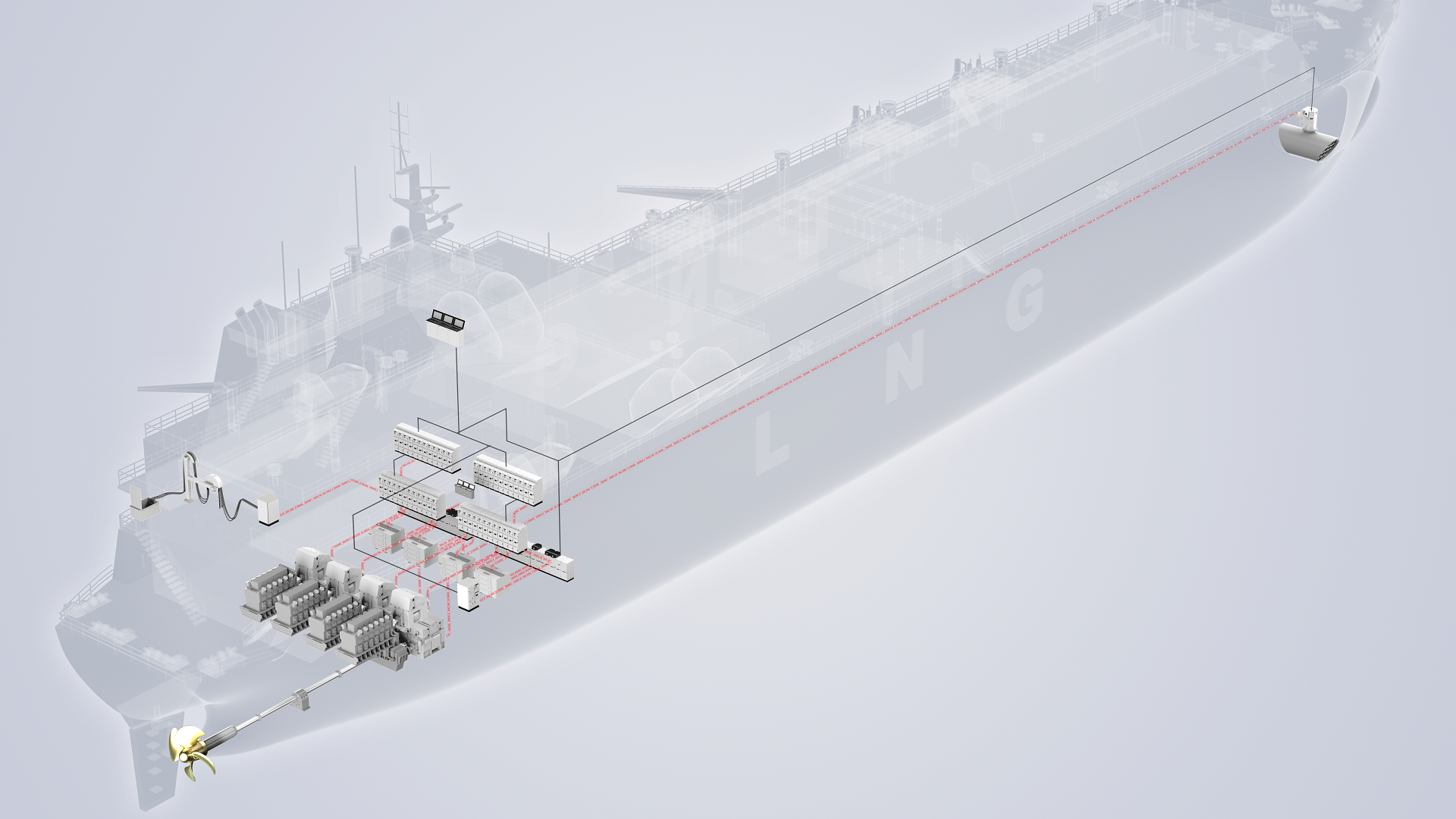

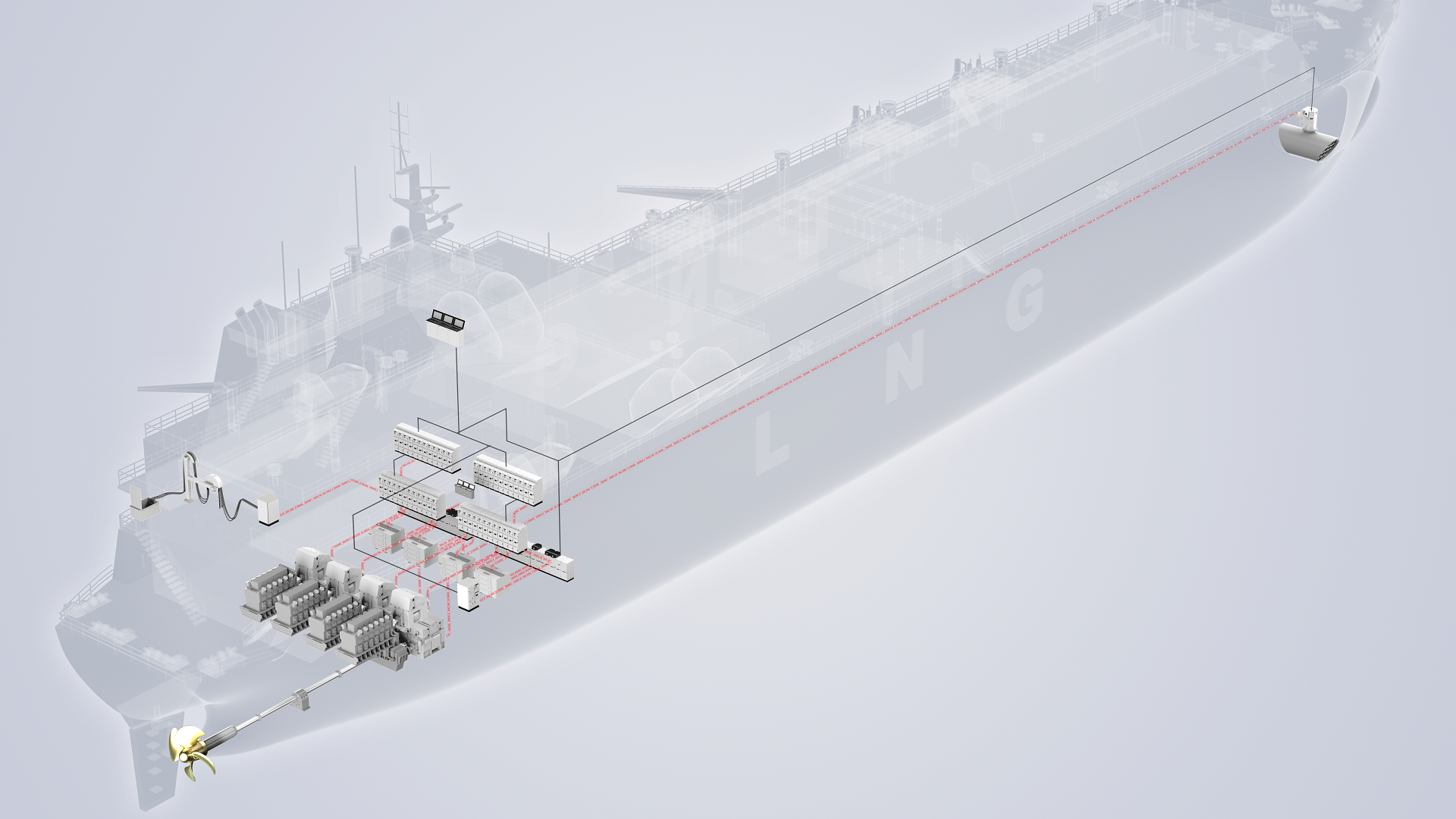

Compressor

Winch and deck machinery

Main Propulsion

Pumps

Thruster

Genset and shaft generator

Compressor

Winch and deck machinery

Main Propulsion

Pumps

Thruster

Genset and shaft generator

LNG

Compressor

Winch and deck machinery

Main Propulsion

Pumps

Thruster

Genset and shaft generator

Compressor

Winch and deck machinery

Main Propulsion

Pumps

Thruster

Genset and shaft generator

Enabling uncompromised productivity for your business

Cover all your possibilities with our all-compatible ACS880 industrial drives designed to tackle any of your motor-driven applications, in any industries, whatever the power range. Our drive is compatible with virtually all of your processes, automation systems, users and business requirements. The innovation behind the ACS880 drives is our drives architecture that simplifies operation, optimizes energy efficiency and helps maximize process output. The ACS880 series consists of single drives, multidrives and drive modules.

Our ACS880 industrial drives offer you:

For more information visit ABB's website:

https://new.abb.com/drives/low-voltage-ac/industrial-drives

Our offering

ACS880 single drives

ACS880 drive modules

ACS880 multidrives

Industrial ACS800 series

ACS880 liquid-cooled modules

Industrial drives

Our industrial drives provide scalable motor control from standard to demanding applications for a wide range of industries, especially in the process industries such as pulp and paper, metals, mining, cement, power, chemical, oil and gas. The drives are packed with advanced drive technology developed by our engineers and are capable of tackling even the most demanding requirements. A wide voltage and power range with various drive configurations and options enable one drive platform to be used for all needs.

Applications

ABB general purpose drives can be used in a wide range of industries. Typical applications include pump, fan and constant torque use, such as conveyors. ABB standard drives are ideal in those situations where there is a need for simplicity to install, commission and use and where customizing or special product engineering is not required.

Our offerings

For more information visit ABB's website:

http://new.abb.com/drives/medium-voltage-ac-drives

ACS1000

ACS2000

ACS5000

ABB’s high voltage modular induction motors provide high efficiency, reliability and availability in the toughest and most demanding applications.

Built on the most successful modular motor platform, they comply with all relevant international standards, are optimized for variable speed control and undergo rigorous testing at every stage of production.

ABB’s modular induction motors are available as N-series general purpose motors (type NMI) and A-series engineered motors (type AMI).

N-series general purpose motors combine cost-efficient standardized designs and short lead times with safety, productivity, energy efficiency and reliability. They are targeted at applications where a highly customized motor is not needed.

The pre-engineered N-series complements ABB’s A-series of engineered motors, which are highly customized, fine-tuned to the customer’s precise needs, and offer a high degree of engineering flexibility.

For more information visit ABB's website:

http://new.abb.com/motors-generators/high-voltage-induction-motors/modular-induction-motors

Technical data

| Output power | 140 to 23,000 kW at 50 Hz 200 to 30,000 HP at 60 Hz |

| Frame size | IEC 400 to 1,000 NEMA 17 to 44.1 |

| Number of poles | 2 to 24 2-pole for sizes 400-800 |

| Voltages | 380 to 13,800 V |

| Frequency | 50 Hz, 60 Hz |

| Environment | IP23, IP54, IP55, IPW24 IC01, IC611, IC81W |

| Enclosure material | Fabricated steel |

| Motor type | AMA, AMI, NMI |

| Mounting type | Horizontal or vertical |

| Standards | IEC, NEMA, country and customer specific standards |

Developed from the outset for maximum convenience and easy handling, ABB General performance motors can be used in a wide range of industrial applications. These motors are suitable for OEMs to build into pumps and fans, as well as for gearboxes, conveyors, general machinery and other applications. Some standard designs are available from stock, while customer and application specific solutions are manufactured to order and can be tailored to meet specific needs.

For more information visit ABB's website:

https://new.abb.com/motors-generators/iec-low-voltage-motors/general-performance-motors

| Product range | |

| Cast iron | M2BAX - iEC frame sizes 71 to 355 |

| Aluminum | M2AA - IEC frame sizes 56 to 250 |

| Output power | 0.06 to 355 kW |

| Effiency class | IE1, IE2, IE3 |

Process performance motors provide great flexibility for customer specific solutions and can be individually designed to meet the exact demands of the application.

Different technologies are needed to provide the best high efficiency motor solution throughout the power range of low voltage motors. ABB motor will always be fit for purpose to provide the most cost efficient and sustainable solution based on your requirements.

Process performance motors offer you:

Products:

Process performance induction motors

Synchronous reluctance motors

Permanent magnet motors

Water cooled motors

For more information visit ABB's website:

https://new.abb.com/motors-generators/iec-low-voltage-motors/process-performance-motors

| Product range | |

| Cast iron | M3BP - IEC frame sizes 71 to 450 |

| Aluminum | M3AA - IEC frame sizes 63 to 280 |

| Output power | 0.25 to 1000 kW |

| Efficiency class | IE2, IE3, IE4 |

A motor for any application

Our extensive line of General Purpose motors are available in Open Drip-proof and TEFC construction in both single and three phase. Sizes available from stock range from 0.06 – 1119 kW (1/12 - 1500 HP).

Designed for "general purpose" use means that these motors can be used in applications which include compressors, pumps, fans, conveyors, material handling, machine tools and many others.

For more information visit ABB's website:

https://new.abb.com/motors-generators/nema-low-voltage-ac-motors/nema-general-purpose-motors

Our offering:

Always one step ahead

With the help of advanced services, your production, energy consumption and cost management can all be enhanced.

Our remote monitoring and energy efficiency solutions mean your business stays a step ahead. Accurate, real-time information about your energy consumption or drive events will facilitate you making the right decisions about your assets operations at the right time.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/advanced-services

Energy Appraisal service

Do more with less by improving energy efficiency

Highlights

Remote Condition Monitoring service

Always one step ahead – reveal your drive’s true potential

Highlights

Make best decisions – Combine your process know-how with analysis and recommendations by ABB professionals. Best decisions are made together.

Reduce the risk of unexpected downtime – Remote Condition Monitoring helps to anticipate possible faults, operational issues and maintenance needs. Equipment will perform better and last longer.

Monitor topics that are important to you – We can tailor our services to your needs and you can monitor the issues that interest you. Our experts are also always on hand to consult with you.

Do you want the latest technology? But you don´t want to change your equipment? No problem.

We are not only committed to delivering the latest technology in new, world-class motors and generators, but also in the form of upgrades for older products. In fact, the potential for upgrading the installed base is one of the factors driving our constant efforts to develop world-leading technology.

In many cases plant operators can upgrade their existing ABB equipment by retrofitting it with new technology. Upgrades can deliver increased production capacity, lowered energy and maintenance costs and increased lifetime as well as better availability and reliability. We will be pleased to advise you on the feasibility of upgrading your ABB equipment.

Key benefits

Our offering:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/extensions-upgrades-and-retrofits

Getting it completely right from the very start.

That’s the idea behind our professional installation and commissioning services. When you use these services you are making an investment in the long-term trouble free operation of your equipment.

We provide commissioning engineers with extensive experience in motors and generators. Their know-how, backed by the expertise of our design team, makes commissioning fast and smooth and lays the foundation for high reliability and efficiency.

Key benefits

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/installation-and-commissioning

Our proactive maintenance services provide the most efficient and effective way to keep your production running.

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/maintenance

Inspections and Diagnostics - Benefits

Life Cycle Assessment - Benefits

On-site Condition Monitoring - Benefits

Preventive Maintenance - Benefits

Remote Condition Monitoring - Benefits

With the market’s widest service network globally, and service engineers standing by to carry out repairs on-site or in authorized workshops, we can offer different repair options to match your needs.

Key benefits

Our offerings:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/repairs

On-site Repairs

Workshop Repairs

Technical support

When a motor or generator needs replacing, do it the easy way - contact your local ABB representative.

Replacing existing equipment with a new ABB product is a great investment: the new unit’s superior efficiency and performance can ensure a very short payback time. Whether you select a new motor or generator from our wide range of standard items or choose a tailor made unit, we can generally optimize it to replace your existing equipment.

In most cases we will be able to adapt the electrical designs to make the replacement fully interchangeable with the original. Utilizing our know-how and experience, we can easily provide replacements for third party products.

For the plant operator this helps to minimize the downtime, required site work and risks. An added benefit of a tailor made, fully interchangeable replacement is that you may be able to keep your existing machine as a spare.

We will be pleased to help you evaluate the potential to increase production, reliability and availability as well as decrease energy and maintenance costs with a replacement product from ABB.

Key benefits

Our offering:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/replacements

A fully tailored service agreement gives you the best possible fit with your needs.

Our experts will help you to design the ideal agreement for you. The process starts with a free-of-charge risk analysis of all the motor and generator systems at your site. In addition, we will analyze your service requirements – carefully reviewing the condition of your equipment and its importance in your operations – and recommend the most appropriate service agreement.

Our service agreements take your competencies and resources into account and are based on the optimum way of sharing the work. In particular, when technical support or remote troubleshooting services are added to the agreement it becomes critical to have competent personnel present on-site. Based on our recommendation you can select the service elements to include in the agreement. For additional convenience, a number of service plans can be coordinated under a single agreement.

An ABB service agreement is the most efficient way to manage the total life cycle of the motors, generators and mechanical power transmission products at your plant, while minimizing production risks.

Key benefits

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/service-agreements-abb-motor-care

ABB’s motors and generators often play a critical role in the plants in which they operate.

In many cases the complete process would be brought to a halt if the motor or generator stopped working. Downtime may result in considerable costs in terms of lost production, waste and damage, so the availability of this equipment is a top priority.

We supply genuine spare parts, spare part packages and maintenance kits for all ABB motors and generators. We can also provide exchange units for wind power generators. As we are the original equipment manufacturer, you can rely on us to supply the correct part. Where technology has advanced, we may be able to provide a part that is even better than the original. We can also help you to rationalize your on-site spare part stocks.

Key benefits

Our offerings:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/spares-and-consumables

ABB provides training to keep your teams competence up-to-date

We offer training courses to help you build your teams competence, enhance safety, develop your staff’s troubleshooting skills, and maximize the availability of your drives. In addition to e-learning and hands-on courses at local training centers, some of our courses can also be conducted at your facilities.

Classroom training

In our classroom training you will learn about all aspects of drives and their operation and maintenance.

On-site training

Some of our courses can also be conducted at your facilities. Contact your local ABB representative for details or find information about local training services at the ABB University.

E-learning

We offer hundreds of course modules for you and your staff to study online. Training topics range from product features to installation and start-up to maintenance and fault finding.

Find out how to access ABB e-learning courses.

For more information visit ABB's website:

http://new.abb.com/drives/services/training

Our training courses are designed to give your people the specialized skills they need.

Key benefits

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/training

Training for Motors and Generators

Training is offered as in-class programs. In-class programs can be standard or customized, according to your requirements

Code Course name

K700 Rotating electrical machines theory, operation and maintenance

K701 Rotating electrical machines theory, operation and maintenance for oil, gas and petrochemical

industry

K702 Rotating electrical machines theory, operation and maintenance for marine industry

K703 Rotating electrical machines theory, operation and maintenance minerals and mining industry

K704 Diagnosis and condition monitoring of rotating electrical machines

K280 Ex Service seminar for motors and generators for hazardous areas

K251 Synchronous machines training, see link for more information

G911 Electrical machines operation and maintenance (german language)

Always one step ahead

With the help of advanced services, your production, energy consumption and cost management can all be enhanced.

Our remote monitoring and energy efficiency solutions mean your business stays a step ahead. Accurate, real-time information about your energy consumption or drive events will facilitate you making the right decisions about your assets operations at the right time.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/advanced-services

Energy Appraisal service

Do more with less by improving energy efficiency

Highlights

Remote Condition Monitoring service

Always one step ahead – reveal your drive’s true potential

Highlights

Make best decisions – Combine your process know-how with analysis and recommendations by ABB professionals. Best decisions are made together.

Reduce the risk of unexpected downtime – Remote Condition Monitoring helps to anticipate possible faults, operational issues and maintenance needs. Equipment will perform better and last longer.

Monitor topics that are important to you – We can tailor our services to your needs and you can monitor the issues that interest you. Our experts are also always on hand to consult with you.

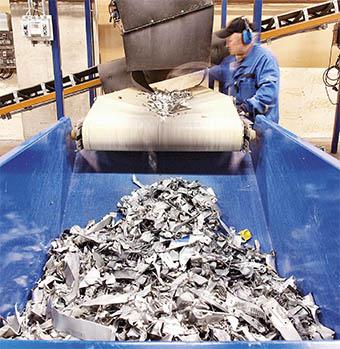

When your ABB drives reach the end of their lives, ABB’s End-of-life services will assist you with disposal and recycling

We behave in an environmentally responsible way throughout every drive’s life cycle, even when it reaches the end of its working life.

Disposal and recycling

We will remove and dispose of any ABB or non-ABB drive and associated equipment in line with the environmental regulations enforced within your country.

Contact your local ABB for further assistance

For more information visit ABB's website:

http://new.abb.com/drives/services/end-of-life-services

Services for your applications needs

Engineering and consulting help in improving the performance of production processes and facilitates effective asset management. We leverage our network to provide the best solutions for you.

Our engineering and consulting services are based on production, safety and energy efficiency analyses of machines and systems. We take care of your specific requirements that you might have during procurement, operation and maintenance of your assets.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/engineering-and-consulting

Engineering Customization service

Tailored solutions for your application needs

Highlights

Functional Safety Assessment service

No compromise on safety and performance

Highlights

Proper installation and commissioning are essential for all drives.

ABB-certified engineers can provide professional installation and commissioning services for you to optimize drives safety, availability and performance. Our expertise also helps you minimize installation and commissioning time and cost.

Installation

Ensure drives reliability right from the start

To help you to correctly install your drives and ensure reliable performance, ABB and third party authorized channel companies can offer you accurate advice and timely support, before and during the installation. On request, ABB certified engineers can also undertake the entire drive installation for you.

Commissioning

Optimize the availability and performance of a new drive application with professional commissioning

We offer services that help you get more from your drive from the moment it’s commissioned. ABB certified engineers will ensure that your drive is commissioned according to local safety regulations and adjust its parameters for the optimum reliability and performance. Well commissioned drives run better, more reliably, use less energy and have a longer life.

All startup information with process parameters will be saved in case an engineer needs to recall any information at a later date.

During the commissioning work, we can provide guidance on drive usage. More extensive training is available separately as an option.

For more information visit ABB's website:

http://new.abb.com/drives/services/installation-and-commissioning

Keep your processes running with ABB’s drive maintenance services

We offer maintenance services that cover everything from life cycle assessment through to detailed preventive maintenance programs. By performing regular maintenance we can maximize your drives reliability and keep your drives going longer.

When we carry out maintenance on your drives, we will take care of tasks pre-defined in product specific maintenance schedules. ABB’s extensive experience in drive maintenance means that we can optimize the service intervals according to the needs of different components and systems within your drives. We also offer drive-specific Preventive Maintenance kits with all the genuine parts you need.

For more information visit ABB's website:

http://new.abb.com/drives/services/maintenance

Our offerings:

Rely on ABB's repair service to restore your operations

Our drive repair services are fast and effective, helping you restore your operations quickly. ABB certified service engineers can provide both on-site repair and workshop repair services, supported by our extensive stock of genuine ABB parts.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/repairs/onsite-service-center

Workshop Repair service

Highlights

On-site Repair service

Highlights

Technical Support

Highlights

On-site Service Center

Highlights

We offer you the world’s widest drives portfolio. Whenever you need to replace an entire drive - from ABB or any other drive manufacturer – we can take care of it.

We will help you select the optimal replacement drive with the correct features for your application.

Simply contact ABB or one of our third party company representatives to request a new drive or exchange unit. In urgent cases we will dispatch your exchange unit within 24 hours from the moment of order. We also offer express delivery services. If you need help with drive’s installation and commissioning, we can provide those services too.

For more information visit ABB's website:

http://new.abb.com/drives/services/replacement

Allow your business to prosper!

Each ABB Drive Care agreement is designed to let you focus on your core business. With a service agreement matching your needs we can reduce the risk of unplanned downtime and make it easier for you to budget maintenance. This means better, more reliable drive performance, extended drive lifetime, and improved cost control.

Highlights

For more information visit ABB's website:

http://new.abb.com/drives/services/abb-drive-care

With ABB, the parts or exchange drives you need are always available

With ABB, the genuine spare parts and exchange units are always available wherever you need them. We provide spare parts for all drive types in the active and classic phases of their life cycle and for some drives in the limited phase. We will also help you select the optimal exchange unit with the correct features for your application. All ABB spares and exchange units come with a one year warranty.

Our offerings

For more information visit ABB's website:

http://new.abb.com/drives/services/spares-and-consumables

Genuine ABB spare parts: global on-time delivery

If a fault is detected within a drive, the right spare part can be delivered as soon as you need it.

Highlights

Drive Exchange service

Exchange operational problem with smooth reliability

Our fully functioning workshop-refurbished drives save you time and costs when replacing units or carrying out preventive maintenance.

Highlights

Optimal cost savings - Save up to 30% of the cost of a new drive, but with the equivalent performance, with our fully tested exchange units.

Trustworthy reliability - Exchange units are fully compatible with your original drives. They are tested according to original specifications and have a one-year warranty.

Green and sustainable - Your original drives are gone but not forgotten. They are either refurbished, used to refill exchange unit stock or recycled according to local regulations.

Enhance and modernize your existing drives with upgrades and retrofits from ABB

Whenever you want to modernize your existing drives, contact ABB. We provide everything from expert advice through to implementation of the latest software and hardware upgrades.

Upgrades and retrofits will improve your drives’ reliability and performance, and extend their functionality. In addition, modernizing your drives ensures support and spares availability.

Modernization services are also available for drives other than ABB.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/upgrades-and-retrofits

Hardware Upgrade

Improve the performance of your drives and extend their functionality with ABB upgrades

Highlights

Control upgrade

Cost-efficient lifetime extension for your drive

Highlights

Retrofit service

Bringing drive technology up-to-date

Highlights

← Back

Motors

High voltage motors

Modular induction motors

IEC Low voltage motors

General performance motors

Process performance motors

NEMA Low voltage motors

NEMA General purpose motors

Services

Motor life cycle services

Advanced Services for motors

Extensions, upgrades and retrofits for motors

Installation and Commissioning for motors

Maintenance for motors

Repairs for motors

Replacement for motors

Service agreements - ABB Motor Care

Spares and Consumables for motors

Training

Drives training

Motor training

VSD life cycle services

Advanced Services for drives

End-of-life services for drives

Engineering and Consulting for drives

Installation and Commissioning for drives

Maintenance for drives

Repairs for drives

Replacement for drives

Service agreements - ABB Drive Care

Spares and Consumables for drives

Upgrades and Retrofits for drives

Variable speed drives - VSD

Low voltage AC drives

Industrial LV drives

Medium voltage AC drives

Industrial MV drives

Enabling uncompromised productivity for your business

Cover all your possibilities with our all-compatible ACS880 industrial drives designed to tackle any of your motor-driven applications, in any industries, whatever the power range. Our drive is compatible with virtually all of your processes, automation systems, users and business requirements. The innovation behind the ACS880 drives is our drives architecture that simplifies operation, optimizes energy efficiency and helps maximize process output. The ACS880 series consists of single drives, multidrives and drive modules.

Our ACS880 industrial drives offer you:

For more information visit ABB's website:

https://new.abb.com/drives/low-voltage-ac/industrial-drives

Our offering

ACS880 single drives

ACS880 drive modules

ACS880 multidrives

Industrial ACS800 series

ACS880 liquid-cooled modules

Industrial drives

Our industrial drives provide scalable motor control from standard to demanding applications for a wide range of industries, especially in the process industries such as pulp and paper, metals, mining, cement, power, chemical, oil and gas. The drives are packed with advanced drive technology developed by our engineers and are capable of tackling even the most demanding requirements. A wide voltage and power range with various drive configurations and options enable one drive platform to be used for all needs.

Applications

ABB general purpose drives can be used in a wide range of industries. Typical applications include pump, fan and constant torque use, such as conveyors. ABB standard drives are ideal in those situations where there is a need for simplicity to install, commission and use and where customizing or special product engineering is not required.

Our offerings

For more information visit ABB's website:

http://new.abb.com/drives/medium-voltage-ac-drives

ACS1000

ACS2000

ACS5000

ABB’s high voltage modular induction motors provide high efficiency, reliability and availability in the toughest and most demanding applications.

Built on the most successful modular motor platform, they comply with all relevant international standards, are optimized for variable speed control and undergo rigorous testing at every stage of production.

ABB’s modular induction motors are available as N-series general purpose motors (type NMI) and A-series engineered motors (type AMI).

N-series general purpose motors combine cost-efficient standardized designs and short lead times with safety, productivity, energy efficiency and reliability. They are targeted at applications where a highly customized motor is not needed.

The pre-engineered N-series complements ABB’s A-series of engineered motors, which are highly customized, fine-tuned to the customer’s precise needs, and offer a high degree of engineering flexibility.

For more information visit ABB's website:

http://new.abb.com/motors-generators/high-voltage-induction-motors/modular-induction-motors

Technical data

| Output power | 140 to 23,000 kW at 50 Hz 200 to 30,000 HP at 60 Hz |

| Frame size | IEC 400 to 1,000 NEMA 17 to 44.1 |

| Number of poles | 2 to 24 2-pole for sizes 400-800 |

| Voltages | 380 to 13,800 V |

| Frequency | 50 Hz, 60 Hz |

| Environment | IP23, IP54, IP55, IPW24 IC01, IC611, IC81W |

| Enclosure material | Fabricated steel |

| Motor type | AMA, AMI, NMI |

| Mounting type | Horizontal or vertical |

| Standards | IEC, NEMA, country and customer specific standards |

Developed from the outset for maximum convenience and easy handling, ABB General performance motors can be used in a wide range of industrial applications. These motors are suitable for OEMs to build into pumps and fans, as well as for gearboxes, conveyors, general machinery and other applications. Some standard designs are available from stock, while customer and application specific solutions are manufactured to order and can be tailored to meet specific needs.

For more information visit ABB's website:

https://new.abb.com/motors-generators/iec-low-voltage-motors/general-performance-motors

| Product range | |

| Cast iron | M2BAX - iEC frame sizes 71 to 355 |

| Aluminum | M2AA - IEC frame sizes 56 to 250 |

| Output power | 0.06 to 355 kW |

| Effiency class | IE1, IE2, IE3 |

Process performance motors provide great flexibility for customer specific solutions and can be individually designed to meet the exact demands of the application.

Different technologies are needed to provide the best high efficiency motor solution throughout the power range of low voltage motors. ABB motor will always be fit for purpose to provide the most cost efficient and sustainable solution based on your requirements.

Process performance motors offer you:

Products:

Process performance induction motors

Synchronous reluctance motors

Permanent magnet motors

Water cooled motors

For more information visit ABB's website:

https://new.abb.com/motors-generators/iec-low-voltage-motors/process-performance-motors

| Product range | |

| Cast iron | M3BP - IEC frame sizes 71 to 450 |

| Aluminum | M3AA - IEC frame sizes 63 to 280 |

| Output power | 0.25 to 1000 kW |

| Efficiency class | IE2, IE3, IE4 |

The permanent magnet motor range extends the effective nominal speed range of the rugged industry workhorses down to 100 – 850 r/min. The motors can simplify drive systems by effectively eliminating the need of speed reduction devices. They are designed exclusively for frequency converter supply, where they provide high speed accuracy even without speed sensors because they are synchronous motors without rotor slip.

Features

The most common present drive systems, which permanent magnet motor solution could replace:

For more information visit ABB's website:

https://new.abb.com/motors-generators/iec-low-voltage-motors/process-performance-motors/permanent-magnet-motors

| Output power | 0 - 220 r/min, 17 - 1120 kW at 220 r/min 0 - 300 r/min, 25 - 1600 kW at 300 r/min 0 - 430 r/min, 38 - 2240 kW at 430 r/min 0 - 600 r/min, 57 - 2500 kW at 600 r/min |

| Frame size | IEC 280 to 560 |

| Frame material | Cast iron/Welded steel |

| Voltages | All voltages |

| Protection | IP 55 |

| Cooling | Air or liquid |

Get the best of both worlds.

The advantages of permanent magnet technology together with the simplicity and service-friendliness of an induction platform. Each motor-drive package combines proven stator technology, an innovative magnet-free rotor design, a best-in-class industrial drive and advanced software to offer a complete, optimized solution.

Our offerings

For more information visit ABB's website:

http://new.abb.com/motors-generators/iec-low-voltage-motors/frequency-controlled-motors/synchronous-reluctance-motor-drive-packages

High output SynRM motor-drive packages

IE4 SynRM motor-drive packages

ACS850 - machinery drive

ABB Industrial drive, ACS880

ABB Industry-specific drive, ACQ810

A motor for any application

Our extensive line of General Purpose motors are available in Open Drip-proof and TEFC construction in both single and three phase. Sizes available from stock range from 0.06 – 1119 kW (1/12 - 1500 HP).

Designed for "general purpose" use means that these motors can be used in applications which include compressors, pumps, fans, conveyors, material handling, machine tools and many others.

For more information visit ABB's website:

https://new.abb.com/motors-generators/nema-low-voltage-ac-motors/nema-general-purpose-motors

Our offering:

Always one step ahead

With the help of advanced services, your production, energy consumption and cost management can all be enhanced.

Our remote monitoring and energy efficiency solutions mean your business stays a step ahead. Accurate, real-time information about your energy consumption or drive events will facilitate you making the right decisions about your assets operations at the right time.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/advanced-services

Energy Appraisal service

Do more with less by improving energy efficiency

Highlights

Remote Condition Monitoring service

Always one step ahead – reveal your drive’s true potential

Highlights

Make best decisions – Combine your process know-how with analysis and recommendations by ABB professionals. Best decisions are made together.

Reduce the risk of unexpected downtime – Remote Condition Monitoring helps to anticipate possible faults, operational issues and maintenance needs. Equipment will perform better and last longer.

Monitor topics that are important to you – We can tailor our services to your needs and you can monitor the issues that interest you. Our experts are also always on hand to consult with you.

Do you want the latest technology? But you don´t want to change your equipment? No problem.

We are not only committed to delivering the latest technology in new, world-class motors and generators, but also in the form of upgrades for older products. In fact, the potential for upgrading the installed base is one of the factors driving our constant efforts to develop world-leading technology.

In many cases plant operators can upgrade their existing ABB equipment by retrofitting it with new technology. Upgrades can deliver increased production capacity, lowered energy and maintenance costs and increased lifetime as well as better availability and reliability. We will be pleased to advise you on the feasibility of upgrading your ABB equipment.

Key benefits

Our offering:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/extensions-upgrades-and-retrofits

Getting it completely right from the very start.

That’s the idea behind our professional installation and commissioning services. When you use these services you are making an investment in the long-term trouble free operation of your equipment.

We provide commissioning engineers with extensive experience in motors and generators. Their know-how, backed by the expertise of our design team, makes commissioning fast and smooth and lays the foundation for high reliability and efficiency.

Key benefits

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/installation-and-commissioning

Our proactive maintenance services provide the most efficient and effective way to keep your production running.

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/maintenance

Inspections and Diagnostics - Benefits

Life Cycle Assessment - Benefits

On-site Condition Monitoring - Benefits

Preventive Maintenance - Benefits

Remote Condition Monitoring - Benefits

With the market’s widest service network globally, and service engineers standing by to carry out repairs on-site or in authorized workshops, we can offer different repair options to match your needs.

Key benefits

Our offerings:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/repairs

On-site Repairs

Workshop Repairs

Technical support

When a motor or generator needs replacing, do it the easy way - contact your local ABB representative.

Replacing existing equipment with a new ABB product is a great investment: the new unit’s superior efficiency and performance can ensure a very short payback time. Whether you select a new motor or generator from our wide range of standard items or choose a tailor made unit, we can generally optimize it to replace your existing equipment.

In most cases we will be able to adapt the electrical designs to make the replacement fully interchangeable with the original. Utilizing our know-how and experience, we can easily provide replacements for third party products.

For the plant operator this helps to minimize the downtime, required site work and risks. An added benefit of a tailor made, fully interchangeable replacement is that you may be able to keep your existing machine as a spare.

We will be pleased to help you evaluate the potential to increase production, reliability and availability as well as decrease energy and maintenance costs with a replacement product from ABB.

Key benefits

Our offering:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/replacements

A fully tailored service agreement gives you the best possible fit with your needs.

Our experts will help you to design the ideal agreement for you. The process starts with a free-of-charge risk analysis of all the motor and generator systems at your site. In addition, we will analyze your service requirements – carefully reviewing the condition of your equipment and its importance in your operations – and recommend the most appropriate service agreement.

Our service agreements take your competencies and resources into account and are based on the optimum way of sharing the work. In particular, when technical support or remote troubleshooting services are added to the agreement it becomes critical to have competent personnel present on-site. Based on our recommendation you can select the service elements to include in the agreement. For additional convenience, a number of service plans can be coordinated under a single agreement.

An ABB service agreement is the most efficient way to manage the total life cycle of the motors, generators and mechanical power transmission products at your plant, while minimizing production risks.

Key benefits

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/service-agreements-abb-motor-care

ABB’s motors and generators often play a critical role in the plants in which they operate.

In many cases the complete process would be brought to a halt if the motor or generator stopped working. Downtime may result in considerable costs in terms of lost production, waste and damage, so the availability of this equipment is a top priority.

We supply genuine spare parts, spare part packages and maintenance kits for all ABB motors and generators. We can also provide exchange units for wind power generators. As we are the original equipment manufacturer, you can rely on us to supply the correct part. Where technology has advanced, we may be able to provide a part that is even better than the original. We can also help you to rationalize your on-site spare part stocks.

Key benefits

Our offerings:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/spares-and-consumables

ABB provides training to keep your teams competence up-to-date

We offer training courses to help you build your teams competence, enhance safety, develop your staff’s troubleshooting skills, and maximize the availability of your drives. In addition to e-learning and hands-on courses at local training centers, some of our courses can also be conducted at your facilities.

Classroom training

In our classroom training you will learn about all aspects of drives and their operation and maintenance.

On-site training

Some of our courses can also be conducted at your facilities. Contact your local ABB representative for details or find information about local training services at the ABB University.

E-learning

We offer hundreds of course modules for you and your staff to study online. Training topics range from product features to installation and start-up to maintenance and fault finding.

Find out how to access ABB e-learning courses.

For more information visit ABB's website:

http://new.abb.com/drives/services/training

Our training courses are designed to give your people the specialized skills they need.

Key benefits

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/training

Training for Motors and Generators

Training is offered as in-class programs. In-class programs can be standard or customized, according to your requirements

Code Course name

K700 Rotating electrical machines theory, operation and maintenance

K701 Rotating electrical machines theory, operation and maintenance for oil, gas and petrochemical

industry

K702 Rotating electrical machines theory, operation and maintenance for marine industry

K703 Rotating electrical machines theory, operation and maintenance minerals and mining industry

K704 Diagnosis and condition monitoring of rotating electrical machines

K280 Ex Service seminar for motors and generators for hazardous areas

K251 Synchronous machines training, see link for more information

G911 Electrical machines operation and maintenance (german language)

Always one step ahead

With the help of advanced services, your production, energy consumption and cost management can all be enhanced.

Our remote monitoring and energy efficiency solutions mean your business stays a step ahead. Accurate, real-time information about your energy consumption or drive events will facilitate you making the right decisions about your assets operations at the right time.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/advanced-services

Energy Appraisal service

Do more with less by improving energy efficiency

Highlights

Remote Condition Monitoring service

Always one step ahead – reveal your drive’s true potential

Highlights

Make best decisions – Combine your process know-how with analysis and recommendations by ABB professionals. Best decisions are made together.

Reduce the risk of unexpected downtime – Remote Condition Monitoring helps to anticipate possible faults, operational issues and maintenance needs. Equipment will perform better and last longer.

Monitor topics that are important to you – We can tailor our services to your needs and you can monitor the issues that interest you. Our experts are also always on hand to consult with you.

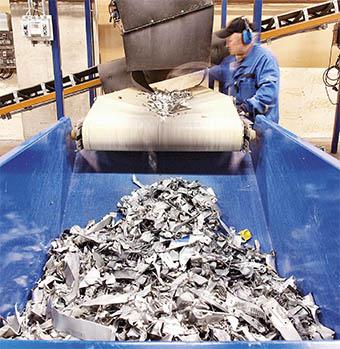

When your ABB drives reach the end of their lives, ABB’s End-of-life services will assist you with disposal and recycling

We behave in an environmentally responsible way throughout every drive’s life cycle, even when it reaches the end of its working life.

Disposal and recycling

We will remove and dispose of any ABB or non-ABB drive and associated equipment in line with the environmental regulations enforced within your country.

Contact your local ABB for further assistance

For more information visit ABB's website:

http://new.abb.com/drives/services/end-of-life-services

Proper installation and commissioning are essential for all drives.

ABB-certified engineers can provide professional installation and commissioning services for you to optimize drives safety, availability and performance. Our expertise also helps you minimize installation and commissioning time and cost.

Installation

Ensure drives reliability right from the start

To help you to correctly install your drives and ensure reliable performance, ABB and third party authorized channel companies can offer you accurate advice and timely support, before and during the installation. On request, ABB certified engineers can also undertake the entire drive installation for you.

Commissioning

Optimize the availability and performance of a new drive application with professional commissioning

We offer services that help you get more from your drive from the moment it’s commissioned. ABB certified engineers will ensure that your drive is commissioned according to local safety regulations and adjust its parameters for the optimum reliability and performance. Well commissioned drives run better, more reliably, use less energy and have a longer life.

All startup information with process parameters will be saved in case an engineer needs to recall any information at a later date.

During the commissioning work, we can provide guidance on drive usage. More extensive training is available separately as an option.

For more information visit ABB's website:

http://new.abb.com/drives/services/installation-and-commissioning

Services for your applications needs

Engineering and consulting help in improving the performance of production processes and facilitates effective asset management. We leverage our network to provide the best solutions for you.

Our engineering and consulting services are based on production, safety and energy efficiency analyses of machines and systems. We take care of your specific requirements that you might have during procurement, operation and maintenance of your assets.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/engineering-and-consulting

Engineering Customization service

Tailored solutions for your application needs

Highlights

Functional Safety Assessment service

No compromise on safety and performance

Highlights

Keep your processes running with ABB’s drive maintenance services

We offer maintenance services that cover everything from life cycle assessment through to detailed preventive maintenance programs. By performing regular maintenance we can maximize your drives reliability and keep your drives going longer.

When we carry out maintenance on your drives, we will take care of tasks pre-defined in product specific maintenance schedules. ABB’s extensive experience in drive maintenance means that we can optimize the service intervals according to the needs of different components and systems within your drives. We also offer drive-specific Preventive Maintenance kits with all the genuine parts you need.

For more information visit ABB's website:

http://new.abb.com/drives/services/maintenance

Our offerings:

Rely on ABB's repair service to restore your operations

Our drive repair services are fast and effective, helping you restore your operations quickly. ABB certified service engineers can provide both on-site repair and workshop repair services, supported by our extensive stock of genuine ABB parts.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/repairs/onsite-service-center

Workshop Repair service

Highlights

On-site Repair service

Highlights

Technical Support

Highlights

On-site Service Center

Highlights

We offer you the world’s widest drives portfolio. Whenever you need to replace an entire drive - from ABB or any other drive manufacturer – we can take care of it.

We will help you select the optimal replacement drive with the correct features for your application.

Simply contact ABB or one of our third party company representatives to request a new drive or exchange unit. In urgent cases we will dispatch your exchange unit within 24 hours from the moment of order. We also offer express delivery services. If you need help with drive’s installation and commissioning, we can provide those services too.

For more information visit ABB's website:

http://new.abb.com/drives/services/replacement

Allow your business to prosper!

Each ABB Drive Care agreement is designed to let you focus on your core business. With a service agreement matching your needs we can reduce the risk of unplanned downtime and make it easier for you to budget maintenance. This means better, more reliable drive performance, extended drive lifetime, and improved cost control.

Highlights

For more information visit ABB's website:

http://new.abb.com/drives/services/abb-drive-care

With ABB, the parts or exchange drives you need are always available

With ABB, the genuine spare parts and exchange units are always available wherever you need them. We provide spare parts for all drive types in the active and classic phases of their life cycle and for some drives in the limited phase. We will also help you select the optimal exchange unit with the correct features for your application. All ABB spares and exchange units come with a one year warranty.

Our offerings

For more information visit ABB's website:

http://new.abb.com/drives/services/spares-and-consumables

Genuine ABB spare parts: global on-time delivery

If a fault is detected within a drive, the right spare part can be delivered as soon as you need it.

Highlights

Drive Exchange service

Exchange operational problem with smooth reliability

Our fully functioning workshop-refurbished drives save you time and costs when replacing units or carrying out preventive maintenance.

Highlights

Optimal cost savings - Save up to 30% of the cost of a new drive, but with the equivalent performance, with our fully tested exchange units.

Trustworthy reliability - Exchange units are fully compatible with your original drives. They are tested according to original specifications and have a one-year warranty.

Green and sustainable - Your original drives are gone but not forgotten. They are either refurbished, used to refill exchange unit stock or recycled according to local regulations.

Enhance and modernize your existing drives with upgrades and retrofits from ABB

Whenever you want to modernize your existing drives, contact ABB. We provide everything from expert advice through to implementation of the latest software and hardware upgrades.

Upgrades and retrofits will improve your drives’ reliability and performance, and extend their functionality. In addition, modernizing your drives ensures support and spares availability.

Modernization services are also available for drives other than ABB.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/upgrades-and-retrofits

Hardware Upgrade

Improve the performance of your drives and extend their functionality with ABB upgrades

Highlights

Control upgrade

Cost-efficient lifetime extension for your drive

Highlights

Retrofit service

Bringing drive technology up-to-date

Highlights

← Back

Motors

High voltage motors

Modular induction motors

IEC Low voltage motors

General performance motors

Process performance motors

Permanent magnet motors

Synchronous reluctance motor-drive package

NEMA Low voltage motors

NEMA General purpose motors

Services

Motor life cycle services

Advanced Services for motors

Extensions, upgrades and retrofits for motors

Installation and Commissioning for motors

Maintenance for motors

Repairs for motors

Replacement for motors

Service agreements - ABB Motor Care

Spares and Consumables for motors

Training

Drives training

Motor training

VSD life cycle services

Advanced Services for drives

End-of-life services for drives

Installation and Commissioning for drives

Engineering and Consulting for drives

Maintenance for drives

Repairs for drives

Replacement for drives

Service agreements - ABB Drive Care

Spares and Consumables for drives

Upgrades and Retrofits for drives

Variable speed drives - VSD

Low voltage AC drives

Industrial LV drives

Medium voltage AC drives

Industrial MV drives

Enabling uncompromised productivity for your business

Cover all your possibilities with our all-compatible ACS880 industrial drives designed to tackle any of your motor-driven applications, in any industries, whatever the power range. Our drive is compatible with virtually all of your processes, automation systems, users and business requirements. The innovation behind the ACS880 drives is our drives architecture that simplifies operation, optimizes energy efficiency and helps maximize process output. The ACS880 series consists of single drives, multidrives and drive modules.

Our ACS880 industrial drives offer you:

For more information visit ABB's website:

https://new.abb.com/drives/low-voltage-ac/industrial-drives

Our offering

ACS880 single drives

ACS880 drive modules

ACS880 multidrives

Industrial ACS800 series

ACS880 liquid-cooled modules

Industrial drives

Our industrial drives provide scalable motor control from standard to demanding applications for a wide range of industries, especially in the process industries such as pulp and paper, metals, mining, cement, power, chemical, oil and gas. The drives are packed with advanced drive technology developed by our engineers and are capable of tackling even the most demanding requirements. A wide voltage and power range with various drive configurations and options enable one drive platform to be used for all needs.

Applications

ABB general purpose drives can be used in a wide range of industries. Typical applications include pump, fan and constant torque use, such as conveyors. ABB standard drives are ideal in those situations where there is a need for simplicity to install, commission and use and where customizing or special product engineering is not required.

Our offerings

For more information visit ABB's website:

http://new.abb.com/drives/medium-voltage-ac-drives

ACS1000

ACS2000

ACS5000

We are a major supplier of brushless synchronous generators for diesel and gas engines. These are in use all over the world, producing power in electric utilities and district heating plants, industrial plants, the marine and offshore sectors, and similar applications. In every case we work with our customers, using our application-specific know-how to ensure that your specific needs are met.

Our products are designed to provide high levels of efficiency over a long service life with low overall life cycle costs, up to 90% of the parts of the product can be recycled.

Benefits

For more information visit ABB's website:

https://new.abb.com/motors-generators/generators/generators-for-diesel-and-gas-engines/high-voltage-generators-for-diesel-and-gas-engines

| Output power | 1 - 60 MVA at 50/60 Hz |

| Voltage | 1 - 15 kV |

| Frame size | 0500 to 2500 |

| Number of poles | 4 - 30 |

| Protection | IP23, IPW24, IP44, IP54, IP55 |

| Cooling | IC01, IC611, IC81W |

| Standards | IEC and NEMA |

| Design | Generators with brushless type excitation are available as open ventilated, totally enclosed as water cooled or duct ventilated design for horizontal mounting. |

| Enclosure material | welded steel |

| Marine classification | all international societies, e.g. ABS, BV, CCS, CR, DNV, GL, KR, LR, NK, RINA, and RS |

For more information visit ABB's website:

https://new.abb.com/motors-generators/generators/generators-for-diesel-and-gas-engines/low-voltage-generators-for-marine-applications

Typical technical data |

|

|

Frame sizes |

180 – 450 |

|

Poles |

4 |

|

Power range |

13 – 2430 kVA |

|

Voltage level |

380 – 440 V at 50 Hz |

|

Speed range |

1500 or 1800 rpm, (50 or 60 Hz) |

ABB’s high voltage modular induction motors provide high efficiency, reliability and availability in the toughest and most demanding applications.

Built on the most successful modular motor platform, they comply with all relevant international standards, are optimized for variable speed control and undergo rigorous testing at every stage of production.

ABB’s modular induction motors are available as N-series general purpose motors (type NMI) and A-series engineered motors (type AMI).

N-series general purpose motors combine cost-efficient standardized designs and short lead times with safety, productivity, energy efficiency and reliability. They are targeted at applications where a highly customized motor is not needed.

The pre-engineered N-series complements ABB’s A-series of engineered motors, which are highly customized, fine-tuned to the customer’s precise needs, and offer a high degree of engineering flexibility.

For more information visit ABB's website:

http://new.abb.com/motors-generators/high-voltage-induction-motors/modular-induction-motors

Technical data

| Output power | 140 to 23,000 kW at 50 Hz 200 to 30,000 HP at 60 Hz |

| Frame size | IEC 400 to 1,000 NEMA 17 to 44.1 |

| Number of poles | 2 to 24 2-pole for sizes 400-800 |

| Voltages | 380 to 13,800 V |

| Frequency | 50 Hz, 60 Hz |

| Environment | IP23, IP54, IP55, IPW24 IC01, IC611, IC81W |

| Enclosure material | Fabricated steel |

| Motor type | AMA, AMI, NMI |

| Mounting type | Horizontal or vertical |

| Standards | IEC, NEMA, country and customer specific standards |

ABB is the market’s leading supplier of synchronous motors and generators. All over the world our synchronous motors deliver high performance in industrial processes, the marine and offshore sectors, utilities, and specialized applications.

Designed to provide extremely high reliability and efficiency, these motors help our customers to cut operating, maintenance and energy costs while lowering environmental impact. Our global service network and predefined maintenance programs ensure support for all life cycle stages of ABB motors

Our offering:

For more information visit ABB's website:

http://new.abb.com/motors-generators/synchronous-motors

Our offering

Developed from the outset for maximum convenience and easy handling, ABB General performance motors can be used in a wide range of industrial applications. These motors are suitable for OEMs to build into pumps and fans, as well as for gearboxes, conveyors, general machinery and other applications. Some standard designs are available from stock, while customer and application specific solutions are manufactured to order and can be tailored to meet specific needs.

For more information visit ABB's website:

https://new.abb.com/motors-generators/iec-low-voltage-motors/general-performance-motors

| Product range | |

| Cast iron | M2BAX - iEC frame sizes 71 to 355 |

| Aluminum | M2AA - IEC frame sizes 56 to 250 |

| Output power | 0.06 to 355 kW |

| Effiency class | IE1, IE2, IE3 |

The permanent magnet motor range extends the effective nominal speed range of the rugged industry workhorses down to 100 – 850 r/min. The motors can simplify drive systems by effectively eliminating the need of speed reduction devices. They are designed exclusively for frequency converter supply, where they provide high speed accuracy even without speed sensors because they are synchronous motors without rotor slip.

Features

The most common present drive systems, which permanent magnet motor solution could replace:

For more information visit ABB's website:

https://new.abb.com/motors-generators/iec-low-voltage-motors/process-performance-motors/permanent-magnet-motors

| Output power | 0 - 220 r/min, 17 - 1120 kW at 220 r/min 0 - 300 r/min, 25 - 1600 kW at 300 r/min 0 - 430 r/min, 38 - 2240 kW at 430 r/min 0 - 600 r/min, 57 - 2500 kW at 600 r/min |

| Frame size | IEC 280 to 560 |

| Frame material | Cast iron/Welded steel |

| Voltages | All voltages |

| Protection | IP 55 |

| Cooling | Air or liquid |

Process performance motors provide great flexibility for customer specific solutions and can be individually designed to meet the exact demands of the application.

Different technologies are needed to provide the best high efficiency motor solution throughout the power range of low voltage motors. ABB motor will always be fit for purpose to provide the most cost efficient and sustainable solution based on your requirements.

Process performance motors offer you:

Products:

Process performance induction motors

Synchronous reluctance motors

Permanent magnet motors

Water cooled motors

For more information visit ABB's website:

https://new.abb.com/motors-generators/iec-low-voltage-motors/process-performance-motors

| Product range | |

| Cast iron | M3BP - IEC frame sizes 71 to 450 |

| Aluminum | M3AA - IEC frame sizes 63 to 280 |

| Output power | 0.25 to 1000 kW |

| Efficiency class | IE2, IE3, IE4 |

Output power - 90 to 2000 kW

Frame size - IEC 280 to 500

Number of poles - 2 to 8

Voltages - All commonly used voltages

Frequency - 50 or 60 Hz

Protection - IP 55, IP 56

Cooling - IC71W

A high efficiency motor fulfills IE2 requirements

A motor for any application

Our extensive line of General Purpose motors are available in Open Drip-proof and TEFC construction in both single and three phase. Sizes available from stock range from 0.06 – 1119 kW (1/12 - 1500 HP).

Designed for "general purpose" use means that these motors can be used in applications which include compressors, pumps, fans, conveyors, material handling, machine tools and many others.

For more information visit ABB's website:

https://new.abb.com/motors-generators/nema-low-voltage-ac-motors/nema-general-purpose-motors

Our offering:

Always one step ahead

With the help of advanced services, your production, energy consumption and cost management can all be enhanced.

Our remote monitoring and energy efficiency solutions mean your business stays a step ahead. Accurate, real-time information about your energy consumption or drive events will facilitate you making the right decisions about your assets operations at the right time.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/advanced-services

Energy Appraisal service

Do more with less by improving energy efficiency

Highlights

Remote Condition Monitoring service

Always one step ahead – reveal your drive’s true potential

Highlights

Make best decisions – Combine your process know-how with analysis and recommendations by ABB professionals. Best decisions are made together.

Reduce the risk of unexpected downtime – Remote Condition Monitoring helps to anticipate possible faults, operational issues and maintenance needs. Equipment will perform better and last longer.

Monitor topics that are important to you – We can tailor our services to your needs and you can monitor the issues that interest you. Our experts are also always on hand to consult with you.

Do you want the latest technology? But you don´t want to change your equipment? No problem.

We are not only committed to delivering the latest technology in new, world-class motors and generators, but also in the form of upgrades for older products. In fact, the potential for upgrading the installed base is one of the factors driving our constant efforts to develop world-leading technology.

In many cases plant operators can upgrade their existing ABB equipment by retrofitting it with new technology. Upgrades can deliver increased production capacity, lowered energy and maintenance costs and increased lifetime as well as better availability and reliability. We will be pleased to advise you on the feasibility of upgrading your ABB equipment.

Key benefits

Our offering:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/extensions-upgrades-and-retrofits

Getting it completely right from the very start.

That’s the idea behind our professional installation and commissioning services. When you use these services you are making an investment in the long-term trouble free operation of your equipment.

We provide commissioning engineers with extensive experience in motors and generators. Their know-how, backed by the expertise of our design team, makes commissioning fast and smooth and lays the foundation for high reliability and efficiency.

Key benefits

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/installation-and-commissioning

Our proactive maintenance services provide the most efficient and effective way to keep your production running.

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/maintenance

Inspections and Diagnostics - Benefits

Life Cycle Assessment - Benefits

On-site Condition Monitoring - Benefits

Preventive Maintenance - Benefits

Remote Condition Monitoring - Benefits

With the market’s widest service network globally, and service engineers standing by to carry out repairs on-site or in authorized workshops, we can offer different repair options to match your needs.

Key benefits

Our offerings:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/repairs

On-site Repairs

Workshop Repairs

Technical support

When a motor or generator needs replacing, do it the easy way - contact your local ABB representative.

Replacing existing equipment with a new ABB product is a great investment: the new unit’s superior efficiency and performance can ensure a very short payback time. Whether you select a new motor or generator from our wide range of standard items or choose a tailor made unit, we can generally optimize it to replace your existing equipment.

In most cases we will be able to adapt the electrical designs to make the replacement fully interchangeable with the original. Utilizing our know-how and experience, we can easily provide replacements for third party products.

For the plant operator this helps to minimize the downtime, required site work and risks. An added benefit of a tailor made, fully interchangeable replacement is that you may be able to keep your existing machine as a spare.

We will be pleased to help you evaluate the potential to increase production, reliability and availability as well as decrease energy and maintenance costs with a replacement product from ABB.

Key benefits

Our offering:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/replacements

A fully tailored service agreement gives you the best possible fit with your needs.

Our experts will help you to design the ideal agreement for you. The process starts with a free-of-charge risk analysis of all the motor and generator systems at your site. In addition, we will analyze your service requirements – carefully reviewing the condition of your equipment and its importance in your operations – and recommend the most appropriate service agreement.

Our service agreements take your competencies and resources into account and are based on the optimum way of sharing the work. In particular, when technical support or remote troubleshooting services are added to the agreement it becomes critical to have competent personnel present on-site. Based on our recommendation you can select the service elements to include in the agreement. For additional convenience, a number of service plans can be coordinated under a single agreement.

An ABB service agreement is the most efficient way to manage the total life cycle of the motors, generators and mechanical power transmission products at your plant, while minimizing production risks.

Key benefits

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/service-agreements-abb-motor-care

ABB’s motors and generators often play a critical role in the plants in which they operate.

In many cases the complete process would be brought to a halt if the motor or generator stopped working. Downtime may result in considerable costs in terms of lost production, waste and damage, so the availability of this equipment is a top priority.

We supply genuine spare parts, spare part packages and maintenance kits for all ABB motors and generators. We can also provide exchange units for wind power generators. As we are the original equipment manufacturer, you can rely on us to supply the correct part. Where technology has advanced, we may be able to provide a part that is even better than the original. We can also help you to rationalize your on-site spare part stocks.

Key benefits

Our offerings:

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/spares-and-consumables

ABB provides training to keep your teams competence up-to-date

We offer training courses to help you build your teams competence, enhance safety, develop your staff’s troubleshooting skills, and maximize the availability of your drives. In addition to e-learning and hands-on courses at local training centers, some of our courses can also be conducted at your facilities.

Classroom training

In our classroom training you will learn about all aspects of drives and their operation and maintenance.

On-site training

Some of our courses can also be conducted at your facilities. Contact your local ABB representative for details or find information about local training services at the ABB University.

E-learning

We offer hundreds of course modules for you and your staff to study online. Training topics range from product features to installation and start-up to maintenance and fault finding.

Find out how to access ABB e-learning courses.

For more information visit ABB's website:

http://new.abb.com/drives/services/training

Our training courses are designed to give your people the specialized skills they need.

Key benefits

For more information visit ABB's website:

http://new.abb.com/motors-generators/service/training

Training for Motors and Generators

Training is offered as in-class programs. In-class programs can be standard or customized, according to your requirements

Code Course name

K700 Rotating electrical machines theory, operation and maintenance

K701 Rotating electrical machines theory, operation and maintenance for oil, gas and petrochemical

industry

K702 Rotating electrical machines theory, operation and maintenance for marine industry

K703 Rotating electrical machines theory, operation and maintenance minerals and mining industry

K704 Diagnosis and condition monitoring of rotating electrical machines

K280 Ex Service seminar for motors and generators for hazardous areas

K251 Synchronous machines training, see link for more information

G911 Electrical machines operation and maintenance (german language)

Always one step ahead

With the help of advanced services, your production, energy consumption and cost management can all be enhanced.

Our remote monitoring and energy efficiency solutions mean your business stays a step ahead. Accurate, real-time information about your energy consumption or drive events will facilitate you making the right decisions about your assets operations at the right time.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/advanced-services

Energy Appraisal service

Do more with less by improving energy efficiency

Highlights

Remote Condition Monitoring service

Always one step ahead – reveal your drive’s true potential

Highlights

Make best decisions – Combine your process know-how with analysis and recommendations by ABB professionals. Best decisions are made together.

Reduce the risk of unexpected downtime – Remote Condition Monitoring helps to anticipate possible faults, operational issues and maintenance needs. Equipment will perform better and last longer.

Monitor topics that are important to you – We can tailor our services to your needs and you can monitor the issues that interest you. Our experts are also always on hand to consult with you.

When your ABB drives reach the end of their lives, ABB’s End-of-life services will assist you with disposal and recycling

We behave in an environmentally responsible way throughout every drive’s life cycle, even when it reaches the end of its working life.

Disposal and recycling

We will remove and dispose of any ABB or non-ABB drive and associated equipment in line with the environmental regulations enforced within your country.

Contact your local ABB for further assistance

For more information visit ABB's website:

http://new.abb.com/drives/services/end-of-life-services

Services for your applications needs

Engineering and consulting help in improving the performance of production processes and facilitates effective asset management. We leverage our network to provide the best solutions for you.

Our engineering and consulting services are based on production, safety and energy efficiency analyses of machines and systems. We take care of your specific requirements that you might have during procurement, operation and maintenance of your assets.

Our offerings:

For more information visit ABB's website:

http://new.abb.com/drives/services/engineering-and-consulting

Engineering Customization service

Tailored solutions for your application needs

Highlights

Functional Safety Assessment service

No compromise on safety and performance

Highlights

Proper installation and commissioning are essential for all drives.

ABB-certified engineers can provide professional installation and commissioning services for you to optimize drives safety, availability and performance. Our expertise also helps you minimize installation and commissioning time and cost.

Installation

Ensure drives reliability right from the start

To help you to correctly install your drives and ensure reliable performance, ABB and third party authorized channel companies can offer you accurate advice and timely support, before and during the installation. On request, ABB certified engineers can also undertake the entire drive installation for you.

Commissioning

Optimize the availability and performance of a new drive application with professional commissioning

We offer services that help you get more from your drive from the moment it’s commissioned. ABB certified engineers will ensure that your drive is commissioned according to local safety regulations and adjust its parameters for the optimum reliability and performance. Well commissioned drives run better, more reliably, use less energy and have a longer life.

All startup information with process parameters will be saved in case an engineer needs to recall any information at a later date.

During the commissioning work, we can provide guidance on drive usage. More extensive training is available separately as an option.

For more information visit ABB's website:

http://new.abb.com/drives/services/installation-and-commissioning

Keep your processes running with ABB’s drive maintenance services

We offer maintenance services that cover everything from life cycle assessment through to detailed preventive maintenance programs. By performing regular maintenance we can maximize your drives reliability and keep your drives going longer.

When we carry out maintenance on your drives, we will take care of tasks pre-defined in product specific maintenance schedules. ABB’s extensive experience in drive maintenance means that we can optimize the service intervals according to the needs of different components and systems within your drives. We also offer drive-specific Preventive Maintenance kits with all the genuine parts you need.

For more information visit ABB's website: